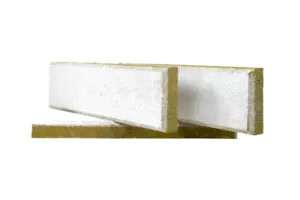

Isover Stropmax 31

Glass wool in the form of plates for acoustic and thermal insulation of ceilings in garages, technical rooms or industrial buildings.

Glass wool in the form of plates for acoustic and thermal insulation of ceilings in garages, technical rooms or industrial buildings.

Product characteristics

Insulating boards made of glass wool Isover. The production is based on the method of pulping the glass melt and other additives and additives. The created mineral fibers are processed into the final shape of the board within the production line. The fibers are hydrophobized over the entire surface. The surface of the insulation is covered with a white glass fleece on the visible side. The boards are exceptionally durable and strong, which makes installation easy.

Usage

Glass wool in the form of plates for acoustic and thermal insulation of ceilings in garages, technical rooms or industrial buildings. A product that meets demanding thermal insulation and acoustic requirements without the need for additional surface treatment. The use of the product assumes the possibility of mechanical anchoring to the structure.

Packaging, transport, storage

Isover Stropmax 31 insulating boards are packed in PE foil. Boards must be transported in covered means of transport, under conditions that exclude their wetting or other deterioration. Products are stored in covered areas according to the conditions specified in Isover's current price list. Products are stored in covered areas or in an external environment according to the conditions indicated in current price list.

Key Facts

- Easy and quick assembly.

- Without the need for additional surface treatment.

- Superior thermal insulation properties.

- Excellent acoustic properties in terms of sound absorption.

- Inflammability (reaction to fire A2-s1).

- Low diffusion resistance - easy permeability for water vapor.

- Ecological and hygienic safety.

- Water repellency - insulating materials are hydrophobized.

- Easy machinability - products can be cut, drilled, etc.

- Dimensional stability during temperature changes.

- Long life.

Varianty produktu

| Thickness (mm) | Length x Width (mm) | Quantity per package (pcs) | Množství v balíku (m2) | Množství v balíku (m3) | Množství na paletě (m2) | Thermal resistance RD (m2·K·W-1) |

|---|---|---|---|---|---|---|

| Thickness (mm)50 | Length x Width (mm)1 200 × 600 | Quantity per package (pcs)12 | Množství v balíku (m2)8,64 | Množství v balíku (m3)0,43 | Množství na paletě (m2)103,68 | Thermal resistance RD (m2·K·W-1)1,60 |

| Thickness (mm)80 | Length x Width (mm)1 200 × 600 | Quantity per package (pcs)7 | Množství v balíku (m2)5,04 | Množství v balíku (m3)0,40 | Množství na paletě (m2)60,48 | Thermal resistance RD (m2·K·W-1)2,55 |

| Thickness (mm)100 | Length x Width (mm)1 200 × 600 | Quantity per package (pcs)6 | Množství v balíku (m2)4,32 | Množství v balíku (m3)0,43 | Množství na paletě (m2)51,84 | Thermal resistance RD (m2·K·W-1)3,20 |

| Thickness (mm)120 | Length x Width (mm)1 200 × 600 | Quantity per package (pcs)5 | Množství v balíku (m2)3,60 | Množství v balíku (m3)0,43 | Množství na paletě (m2)43,20 | Thermal resistance RD (m2·K·W-1)3,85 |

| Thickness (mm)150 | Length x Width (mm)1 200 × 600 | Quantity per package (pcs)4 | Množství v balíku (m2)2,88 | Množství v balíku (m3)0,43 | Množství na paletě (m2)34,56 | Thermal resistance RD (m2·K·W-1)4,80 |

Dokumenty